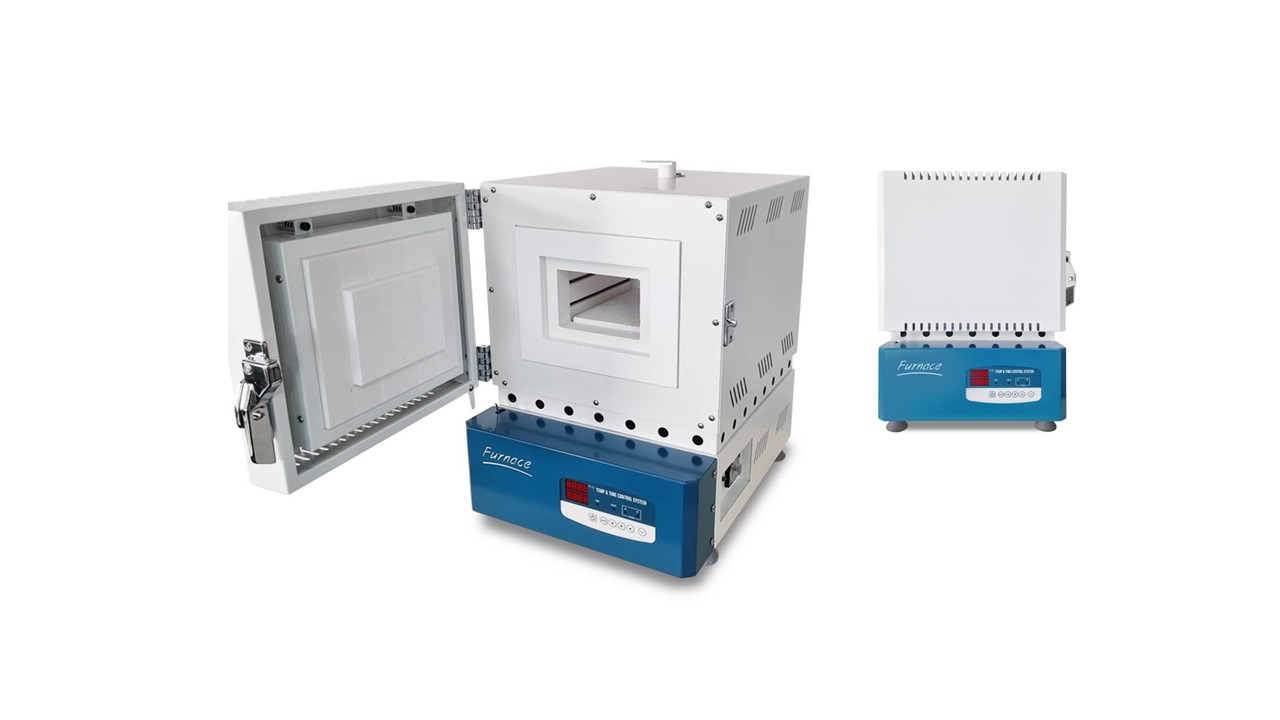

Muffle Furnace

A muffle furnace is a high-temperature laboratory oven used to heat, calcine, sinter, or ash samples. It provides uniform heating while isolating the sample from direct contact with flame or combustion gases.

Product Specification

Max Temp 1200℃ to 1500℃ Muffle Furnace.

- Sensor: K type

- Heater: 1.6kW

- Net weight: 44kg

- Model: SH-FU-5MG

- Insulation: Ceramic

- Chamber volume: 5liters

- Max temperature: 1200℃

- Heating element: Kanthal A-1

- External size: 390x560x580mm

- Controller: Digital PID controller

- Chamber size: 150x300x100mm

- Power supply: 220, 50Hz, 1 phase, 7A

- Continuous running temperature: 1000℃

Product Details:

Main Applications:

A muffle furnace is a high-temperature laboratory oven used to heat, calcine, sinter, or ash samples. It provides uniform heating while isolating the sample from direct contact with flame or combustion gases. It’s commonly used in chemistry, metallurgy, material science, and quality control laboratories.

Smart Features:

√ General muffle furnace with swing door.

√ Double housing and low surface temperature.

√ Recommended ideal running temperature is below 1000°C.

√ Heating from 4 sides and excellent temperature uniformity.

√ 30 steps FC-570 programmable controller available with option.

√ Inert gas atmosphere available with optional ball type flow meter.

√ SSR operation and PID control provides low noise operation and precise temp control.

√ Excellent outgassing thanks to the exhaust air outlet on the head of chamber, plastic polymer.

Applications:

□ Ashing: Determining the inorganic residue in materials.

□ Sample Preparation: Preparing samples for chemical analysis.

□ Burning off Organics: Removing organic content from samples.

□ Heat Treatment: Annealing, sintering, or tempering metals or ceramics.

□ Testing & Quality Control: Checking material stability, moisture content, or impurities.

Rapid heating: Our MG furnaces reach 800°C in less than 40 minutes.

Multiple sizes available: Choose among several standard capacity options.

“If you need more information regarding different model, or working capacity, feel free to contact with our technical team.”

We're Here To Help!

Office

83/B, Shiddeshwari Circular Road, Mouchak Tower (15th Floor), Ramna, Dhaka-1217, Bangladesh.

Hours

S-Tu: 09 am - 07pm

F-F: Closed

Call Us

- +8801773-808081

- +8801642-110290